Epson Sidm Adjustment Program

Posted : admin On 02.09.2019For LX-300+II, LX-1170II Adjustment Tool for SIDM, v.1.40. I can't download file Epson SureColor SC-F2000 Service Program V1.4.1 Epson sc f6000 Epson 4900.

Epson Adjustment Program: Hello Everyone Learn About Epson ink Jet Printer we Are Talking Best topic of And Solution What Problems In Epson Printer Regularly Most Errors Waste Ink Pad Counters Reached Maximum Limit To Sown Errors Service Required Or All Led Lights Blinking On Printer And Not Printing Any More Documents Don't Worry We Have Solution Here What is Solution? Need To Reset Printer. But How To Reset Printer? You Most What Resetter Software For Epson Printers Waste Ink Pad Counters Reset That Is How to Retet Epson Printers Read Continue.

. SERVICE MANUAL 9-pin Serial Impact Dot Matrix Printer EPSON LX-300+II LX-300+II LX-300+II RTP LX-1170II LX-300+II LX-1170II 410687104. SEIKO EPSON CORPORATION.

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON would greatly appreciate being informed of them. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/RATING PLATE. IF THE EPSON PRODUCT HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT CONNECT IT TO THE POWER SOURCE.

Provides preventive maintenance procedures and the related to a specific subject, or comment on the results achieved through a previous action. Lists of Epson-approved lubricants and adhesives required for servicing the product. Indicates an operating or maintenance procedure, practice APPENDIXProvides the following additional information for reference.

Total print volume- Mean print volume between failure (MVBF)(MTBF 25% duty cycle). page -35 Reply EEPROM data in the specific address request for LX-300+II is added. page -35 Reply EEPROM data in the specific address request for LX-1170II is added. 1.7 Paper Specifications.36 1.1 FEATURES.9 1.8 Physical Specifications.39 1.2 SPECIFICATIONS.10 1.8.1 Physical Specifications for LX-300+II.39 1.2.1 Printing Specification.10 1.8.2 Physical Specifications for LX-1170II.40 1.2.2 Paper Feeding. 12 1.9 Accessories. Chapter 4 Disassembly and Assembly Chapter 7 LX-300+II RTP 4.1 Overview.66 7.1 DISASSEMBLY AND ASSEMBLY. 98 4.1.1 Precautions.66 7.1.1 Printhead Unit Removal.99 4.1.2 Tools.66 7.1.2 Upper Housing Unit Removal.100 4.1.3 Service Checks After Repair.

C H A P T E R PRODUCT DESCRIPTION. No recoil cfg css. LX-1170II ESC/P and IBM 2381 Plus emulation EPSON LX-300+II/300+II RTP/1170II is a 9 pin serial impact dot matrix printer. The main Copy capability: 1 original + 4 copies difference between LX-300+II and LX-1170II is the width: 80 columns for LX-300+II and . Bit image 60, 72, 80, 90 or 120 Draft condensed 120 or 240 Draft emphasized Control code: LX-300+II ESC/P and IBM 2380 Plus emulation LX-1170II ESC/P and IBM 2381 Plus emulation (Refer to 1.5 “Control codes”) PRODUCT DESCRIPTION SPECIFICATIONS.

EPSON LX-300+II/300+II RTP/1170II Revision D Character tables: International character sets: 13 countries U.S.A France Germany U.K. Standard version (13 character table) Denmark 1 Sweden Italy Spain 1 Italic table PC437 (US, Standard Europe) Japan Norway Denmark 2.

EPSON LX-300+II/300+II RTP/1170II Revision D 1.2.2 Paper Feeding Character tables and typefaces: Table 1-3. Character Tables and Typefaces Feeding method: Friction feed (rear) Character table Bitmap font Push tractor feed (rear) Push and Pull tractor feed (rear) Standard. EPSON LX-300+II/300+II RTP/1170II Revision D 1.2.3 Electrical Specification Paper thickness lever: The paper thickness lever must be set at the proper position as shown below. Electrical Specification Table 1-5. Paper Thickness Lever 120V version 230V version LX-300+II. Printhead life: Black 400 million strokes / wire UL60950 Safety standards Color 100 million strokes / wire (LX-300+II only) CSA C 22.2 No.60950 120V version FCC part15 subpart B class B 1.2.6 Ribbon Cartridge CAN/CSA-CEI/IEC CISPR22 Class B Safety standards EN60950 Table 1-7. BM (Bottom Margin) 4.2 mm or more 4.2 mm or more Recommended Printable Area NOTE: The maximum horizontal recommended printable area is 203.2 mm for LX-300+II/ 345.44 for LX-1170II.

Recommended Printable Area for Cut Sheet PRODUCT DESCRIPTION SPECIFICATIONS. EPSON LX-300+II/300+II RTP/1170II Revision D Envelop Continuous paper Figure 1-3. Recommended Printable Area for Envelop Figure 1-4.

Recommended Printable Area for Continuous Paper Table 1-11. Recommended Printable Area for Envelop Table 1-12. Recommended Printable Area for Continuous Paper.

EPSON LX-300+II/300+II RTP/1170II Revision D Roll paper Figure 1-5. Recommended Printable Area for Roll Paper Table 1-13. Recommended Printable Area for Roll Paper Continuous Paper PW (Width) Refer to 1.7 “Paper Specifications” PL (Length) Refer to 1.7 “Paper Specifications”. EPSON LX-300+II/300+II RTP/1170II Revision D 1.3 Interface Specifications LX-300+II/LX-1170II is provided with bi-directional 8 bit parallel interface and serial interface and USB interface. Optional interface board is not supported on this model. 1.3.1 Parallel Interface (Forward Channel) Transmission mode: 8 bit parallel IEEE-1284 compatibility mode .

EPSON LX-300+II/300+II RTP/1170II Revision D BUSY signal is active (HIGH level) under the conditions below: Table 1-16. Connector Pin Assignment and Signals (Forward Channel) In the process of receiving data Signal Return In/Out Functional Description Name GND Pin . EPSON LX-300+II/300+II RTP/1170II Revision D 1.3.2 Parallel Interface (Reverse Channel) Table 1-17. Connector Pin Assignment and Signals (Reverse Channel) Transmission mode: IEEE-1284 nibble mode Return Signal Name In/Out Functional Description Adaptable connector: See 1.3.1 “Parallel Interface (Forward Channel)”.

EPSON LX-300+II/300+II RTP/1170II Revision D 1.3.3 Serial Interface Synchronization: Asynchronous Table 1-18. Connector Pin Assignment and Signals Signal level: EIA-232D Signal Name In/Out Functional Description MARK (logical 1): -3V to -25V SPACE (logical 0): +3V to +25V Transmit data. EPSON LX-300+II/300+II RTP/1170II Revision D 1.3.4 USB interface During hardware initialization In the self test mode Standard: based on In the adjustment mode.Universal Serial Bus Specifications Revision 1.1.Universal Serial Bus Device Class Definition for Printing Devices Version 1.1 .

EPSON LX-300+II/300+II RTP/1170II Revision D 1.3.5 Interface Selection 1.3.7 IEEE1284.4 protocol The printer has 3 interfaces; the parallel interface, the serial interface and the USB interface. The packet protocol described by IEEE1284.4 is supported on the parallel I/F and the USB These interfaces are selected manually by Default Setting or selected automatically.

EPSON LX-300+II/300+II RTP/1170II Revision D 1.4 Operation Operation at power on Turning the printer on while pressing panel switches executes the functions below; 1.4.1 Control Panel Table 1-23. Operation at Power On Switch Function 4 switches and 4 LEDs are on the panel as shown below. EPSON LX-300+II/300+II RTP/1170II Revision D 1.4.1.2 Indicators 1.4.1.3 Buzzer Indication in normal mode Paper out error: Beeper sounds (.). Release lever operation error: Beeper sounds (.).

Table 1-25. Indication in normal mode Fatal error: Beeper sounds (-). Color printing position Starts the Color printing position adjustment mode. See “Color And pressing it again moves a next page to the TOF position. Adjustment.

printing position adjustment (LX-300+II Only)” on page -28. Font Bi-d adjustment Starts the Bi-d adjustment mode.

Adjustment” on page -28. Auto CR OFF, ON (IBM 2380/2381 Plus) IBM character table Table2, Table1.1 This setting is effective when IBM 2380 (LX-300+II) or IBM2381 (LX-1170II) Plus emulation is selected.2 Settings with bold weight mean the standard factory settings.

PRODUCT DESCRIPTION Operation. Adjustment for NLQ mode Turn the printer off. The setting is stored into non-volatile memory. 1.4.2.5 Color printing position adjustment (LX-300+II Only) Color printing position alignment can be adjusted by users. Color printing position adjustment method is as follows.

EPSON LX-300+II/300+II RTP/1170II Revision D 1.5 Control codes Table 1-28. ESC/P2 (continued) Classification Operation Command 1.5.1 ESC/P2 Font enhancement Double-Width ESC W, DC4, SO Condensed DC2, SI Table 1-28. ESC/P2 Double-height ESC w Classification Operation Command Double-Strike ESC G, ESC H. Revision D 1.5.2 IBM 2380/2381 Plus Emulation Table 1-29. IBM 2380/2381 Plus emulation (continued) Classification Operation Command LX-300+II/LX-1170II supports not only ESC/P2 but also the following control code. Print position motion Horizontal Print Position ESC d LX-300+II: IBM2380 Initialize Tab Position ESC R . EPSON LX-300+II/300+II RTP/1170II Revision D 1.5.3 Bi-Directional Commands -Save column shows whether SV commands are effective to each feature or not.

Reply printer ID: All parameters are saved., Δ: Some limited parameters are saved.,-: No parameter is . EPSON LX-300+II/300+II RTP/1170II Revision D Table 1-31. Note for Table 1-30 m1 set by AT/CT m2 set by AT m3 set by AT Table 1-34. Bi-Directional Commands Function Code/ Parameter Save All parameters that can be set Set page length “PG”. EPSON LX-300+II/300+II RTP/1170II Revision D 1.5.3.1 Reply Printer Status Table 1-34.

Bi-Directional Commands (continued) Function Code/ Parameter Save The printer sends back one of the five strings shown below every few seconds according to the printer status at that time. EPSON LX-300+II/300+II RTP/1170II Revision D 1.5.3.2 Packet commands Paperpath Table 1-37. PaperPath Table 1-39.

Packet Commands paperpath “” Function Code Continuous paper (rear) “0000” Device ID request “di” 01H 00H 01H Continuous paper (bottom) “0001” Device ID reply. “@EJL”. EPSON LX-300+II/300+II RTP/1170II Revision D 1.6 Initialization Power-on initialization The initialization of this level is activated by power-on or cold-reset command (remote RS command). This initialization is; to initialize the printer mechanism.

Epson Adjustment Program Download

to execute Operator initialization. EPSON LX-300+II/300+II RTP/1170II Revision D 1.7 Paper Specifications Cut sheet (single sheet, not multi part) Cut sheet (multi part) Table 1-41. Cut Sheet (Multi part) Table 1-40. Cut Sheet (single sheet, not multi part) Minimum Maximum Manual insertion. EPSON LX-300+II/300+II RTP/1170II Revision D Envelope Continuous paper (Single sheet and Multipart) Table 1-42. Envelope Table 1-43. Continuous Paper (Single sheet and Multi Part) Minimum Maximum Rear Entry Bottom Entry inch Min.

Width inch 10 (16). EPSON LX-300+II/300+II RTP/1170II Revision D Labels Roll paper Table 1-44. Continuous Paper with Labels Table 1-45. Roll Paper Rear Entry Bottom Entry Minimum Maximum Min. Inch Width Label size See the figure below. Inch 10 (16). Mass: Approx.

4.6 kg Mass: Approx. 4.4 kg Appearance: See the figure below. Appearance: See the figure below. 390.2 390.2 Figure 1-11. Appearance With CSF (LX-300+II) Figure 1-10. Appearance Without Pull Tractor (LX-300+II) PRODUCT DESCRIPTION Physical Specifications.

EPSON LX-300+II/300+II RTP/1170II Revision D 1.8.2 Physical Specifications for LX-1170II Physical Specifications (CSF) Physical Specifications (Without pull tractor) Dimensions: 546 x 440 x 377 mm (WxDxH) Dimensions: 546 x 275 x 159 mm (WxDxH) Except knob, paper guide & paper supports Except knob, paper guide &. EpsonNet 802.11b/g Wireless and Expendables C82437. 10/100 Base Tx Ext. Print Server Table 1-47. Expendables.

These options for LX-300+II and LX-1170II are the same as those for LX-300+ and Description LX-1170, respectively. Enclosed Items LX-300+II LX-1170II Ribbon cartridge (Black ).

C H A P T E R OPERATING PRINCIPLES. EPSON LX-300+II/300+II RTP/1170II Revision D 2.1 Overview LX-300+II/1170II consists of the printer mechanism and electric circuit boards.

Printer Power Supply Mechanism Main Board Board C640/641 C294PSB/PSE MAIN Panel Board C294PNL Figure 2-1. Component Unit Circuit board Table 2-1. EPSON LX-300+II/300+II RTP/1170II Revision D 2.2 Printer Mechanism Ribbon mechanism Color ribbon drive mechanism (option) The following are main components of the LX-300+II/1170II printer mechanism.

Platen gap adjustment mechanism Adjust lever, Platen gap detector Printhead Paper feed mechanism . EPSON LX-300+II/300+II RTP/1170II Revision D 2.2.1 Printhead The table below shows the printhead specifications. Printhead Specifications Item Specification Number of wires Diameter of wire φ0.29 mm See Figure 2-3 'Wire Configuration'. Wire configuration Note: The figure is seen from the back of the head facing printing side.

EPSON LX-300+II/300+II RTP/1170II Revision D 2.2.2 Carriage Mechanism The following are the components of the LX-300+II/1170II carriage mechanism and their explanation. (Figure 2-2, 'Printer Mechanism Block Diagram') Carriage: Mounts the printhead. CR motor: Drives carriage in the printing column direction. EPSON LX-300+II/300+II RTP/1170II Revision D Table 2-5. Carriage Speed Mode Current limit (A/phase) Adjacent Carriage CR drive Phase Head drive Carriage speed High or Printing speed frequency drive frequency Printing speed mode at power low speed Front High Normal Rear. Switching mode. within HP: open Color ribbon driving is only available for LX-300+II.

HP detector detects the signal right after when the CR motor switches the phase. Color ribbon driving mechanism: shifts the color ribbon up and down to change the color area of the ribbon to be used for printing. EPSON LX-300+II/300+II RTP/1170II Revision D RIBBON CARTRIDGE DETECTOR Color ribbon drive circuit Ribbon detector detects if the color ribbon is installed or not. Detect Timing When the power is applied. When recovering from the economy mode. Ribbon detector .

This mechanism is to adjust the distance between the platen and the printhead (platen gap) according to the paper thickness. Carriage The following are the components of the LX-300+II/1170II platen gap adjustment Parallelism adjust mechanism and their explanation. (Refer to Figure 2-5, 'Platen Gap Adjustment. This mechanism consists of the paper feed motor (PF motor), paper feed gears, platen, rear LX-300+II/1170II uses a stepping motor for PF motor. Open loop control switches the paper end detector, bottom paper end detector and push tractor unit.

(Refer to Figure 2-2, phases according to the setting period and this mechanism loads and carries paper to the 'Printer Mechanism Block Diagram'). EPSON LX-300+II/300+II RTP/1170II Revision D 2.2.5.1 Page Length Measurement RPE DETECTOR Page length measurement is a process to convert the following value to the number of RPE detector is installed on the paper path at the back of the printer. The table below shows printing lines. EPSON LX-300+II/300+II RTP/1170II Revision D 2.2.6 Release Mechanism The table below shows the release detector specifications. Release Detector Specifications This mechanism switches the flow of PF motor driving force between to the friction feed and to the tractor feed. EPSON LX-300+II/300+II RTP/1170II Revision D 2.3 Electrical Circuit Operating Principles 2.3.1 MAIN Board Electric Circuit NOTE: CS motor is only available for LX-300+II.

C640/C641 MAIN Board Block Diagram Operating Principles Electrical Circuit Operating Principles. 2.3.2 C294PSB / C294PSE Board CPU: RISC C33208 CPU, QFP 128 pin LX-300+II/1170II generates power supply by a power supply boards: either C294PSB.

Outside clock 19.66 MHz/ (100V) or C294PSE (200V) depending on local supplied voltage. The table below shows Inside clock 39.32 MHz. C H A P T E R TROUBLESHOOTING.

EPSON LX-300+II/300+II RTP/1170II Revision D 3.1 Overview Troubleshooting This chapter describes how to troubleshoot problems if any problems occur with the printer. Refer to troubleshooting flowcharts in this chapter to identify a defective part and an appropriate repair for it. Revision D 3.2 Troubleshooting 3.2.2 Check Performance By Self-Check Function LX-300+II has self-check function, which supervises the printer condition constantly. If 3.2.1 Initialization Check any problem occurs, it indicates an error occurrence by indicator LED and in some cases it notifies the operator of the error occurrence by beeping the buzzer. EPSON LX-300+II/300+II RTP/1170II Revision D 3.2.3 Identify Problems From Symptoms Release Lever Error This error will be indicated when wrong release lever operation is performed. For This section describes the procedure for identifying the problems from the abnormal example, if you change the release lever setting when the printer already starts symptoms.

EPSON LX-300+II/300+II RTP/1170II Revision D Table 3-3. Control Panel LED Does Not Light On. When Power is Applied, the Printer Becomes Fatal Error. Cause Check Point Solution Cause Check Point Solution Check the electric circuit and Are CR motor, timing. EPSON LX-300+II/300+II RTP/1170II Revision D Table 3-6. Self Test Print is Abnormal.

Paper Feed is Abnormal. Cause Check Point Solution Cause Check Point Solution Any of CN3 to CN12 RPE detector or BPE Replace the sensor. Are all connectors Check the sensors. EPSON LX-300+II/300+II RTP/1170II Revision D Table 3-9.

Printing Operation is Abnormal When it is On-Line. Electrical Noise is Caused. (Self-Test is Normal.) Cause Check Point Solution Cause Check Point Solution Is there another Check the initial electrical apparatus. EPSON LX-300+II/300+II RTP/1170II Revision D 3.2.4 Unit and Parts Check 3.2.4.2 Motor Check This section describes the checking method of the printhead, motors and sensors to find the defective units and parts. By measuring the direct current resistance of the motor coil, you can check if the motor is all right. EPSON LX-300+II/300+II RTP/1170II Revision D 3.2.4.3 Sensor Check 3.2.4.4 Printhead Driver Check When the sensor is connected mechanically, you can check the sensor by its conductivity. Simple check of the printer driver (Q3 Q11) can be done by the following method.

C H A P T E R DISASSEMBLY AND ASSEMBLY. 4.1.2 Tools The table below lists the tools recommended to use for disassembly and assembly and This chapter explains the disassembly and assembly of LX-300+II/1170II. Read the adjustment. Use only tools specified here. Precautions below before disassembling and assembling the printer. EPSON LX-300+II/300+II RTP/1170II Revision D Table 4-3.

List of Screws Screw Name Screw Name C.B.P., Tite, 3x10 F/ZN C.P., Screw, 3x4 F/ZN C.P.B., Screw, 3x14 F/ZN C.B(O), Screw, 4x8 F/ZN C.B.S., Screw, 3x4 F/Zn Jack Socket C.B.B., (W(13), 3x14 F/ZN. EPSON LX-300+II/300+II RTP/1170II Revision D 4.1.3 Service Checks After Repair Table 4-4. Check List for Repaired Printer (continued) Category Component Item to Check Check Before returning the printer back to the user, use the check list below to confirm the quality OK NG. EPSON LX-300+II/300+II RTP/1170II Revision D 4.2 Disassembly and Assembly This section explains the disassembly and assembly of LX-300+II/LX-1170II. Unless otherwise specified, assembly can be done in the reverse order of the disassembly procedure.

Anything that service person should pay attention to is described under “Check Point”. Any adjustment required after assembly is described under “Adjustment”. EPSON LX-300+II/300+II RTP/1170II Revision D 4.2.1 Printhead Unit Removal Remove the cover of the printer. Printhead Remove 1 screw (C.P.B., Screw, 3x14 F/ZN; Torque 0.59-0.78N.m) securing the C.P.B., Screw, 3x14 F/ZN printhead to the carriage assembly.

Lift the printhead a little bit. Unlatch 2 hooks securing the printhead FFC to carriage unit. Remove the color upgrade kit if it is installed (LX-300+II only). Set the release lever to the tractor feed.

Upper Housing Remove 4 screws for LX-300+II and 6 screws for LX-1170II (CBP, Tite, 3x10 F/Zn, Torque 0.78-0.98) securing the upper housing to the lower housing.Remove the upper housing. Remove the upper housing. (See 4.2.2 “Upper Housing Unit Removal”.) securing the printer mechanism to the lower housing. LX-300+II: Remove 3 screws (C.B.P., Tite, 3x10 F/ZN;Torque 0.78-0.98 N.M.) See Figure 4-4 below.

Securing the upper shield plate to the lower housing. EPSON LX-300+II/300+II RTP/1170II Revision D 4.2.4 Panel Board Assembly Removal Lift the printer mechanism a little bit and remove the harnesses from the main board assembly.

Remove the upper housing. (See 4.2.2 “Upper Housing Unit Removal”.) Printer Mechanism Main Board Assembly Disconnect the panel FFC from the connector of the panel board assembly. C640/641MAIN Board Assembly Removal parallel interface to the lower shield plate.

Disconnect the option FFC (LX-300+II only) and panel FFC from CN12 and CN13 on the board. Disconnect the harness connected to the Power Supply Board Assembly from CN8. C.B.P., Tite, 3x10 F/ZN C.B.P., Tite, 3x10 F/ZN Remove the printer mechanism. (See 4.2.3 “Printer Mechanism Removal”.) LX-300+II: Remove 1 screw(C.B.P., Tite, 3x10 F/ZN;Torque 0.78-0.98 N.M.) and the left grounding plate.

LX-1170II: Remove 1 screw (C.B(O), Screw, 4x8, F/ZN; Torque 0.98-1.18 N.M.) and the grounding cable. EPSON LX-300+II/300+II RTP/1170II Revision D 4.2.7 Printer Mechanism Disassembly 4.2.7.1 CR Motor Mechanism Removal Remove the printer mechanism. (See 4.2.3 “Printer Mechanism Removal”.) This section explains the disassembling procedure of the printer mechanism. The disassembling procedure is shown in the flowchart below. EPSON LX-300+II/300+II RTP/1170II Revision D 4.2.7.2 Platen Mechanism Removal Remove the printer mechanism. (See 4.2.3 “Printer Mechanism Removal”.) Bushing, 11 Remove the platen grounding wire from the platen. Platen Release 1 hook at the rotating hole of the combination gear 17.5, 27 and remove the gear from the right frame.

EPSON LX-300+II/300+II RTP/1170II Revision D 4.2.7.3 Carriage Mechanism Removal Remove the printer mechanism. (See 4.2.3 “Printer Mechanism Removal”.) PG adjust lever Remove the printhead. (See 4.2.1 “Printhead Unit Removal”.) Remove the timing belt from the carriage installation point.

CR guide shaft. EPSON LX-300+II/300+II RTP/1170II Revision D 4.2.7.4 Ribbon Feed Mechanism Removal Remove the printer mechanism. (See 4.2.3 “Printer Mechanism Removal”.) Remove the tension spring, 8.10 from the motor bracket and release the tension of the timing belt.

(See 4.2.7.1 “CR Motor Mechanism Removal”.) Release 3 hooks securing the RD cover to the left frame. EPSON LX-300+II/300+II RTP/1170II Revision D 4.2.7.5 RPE Sensor Removal 4.2.7.6 BPE Sensor Removal Remove the printer mechanism. (See 4.2.3 “Printer Mechanism Removal”.) Remove the printer mechanism. (See 4.2.3 “Printer Mechanism Removal”.) Release the hook of the RPE sensor installed at the paper guide. EPSON LX-300+II/300+II RTP/1170II Revision D 4.2.7.8 PG Sensor Removal 4.2.7.9 Release Lever Position Sensor Removal Remove the printer mechanism. (See 4.2.3 “Printer Mechanism Removal”.) Remove the printer mechanism.

(See 4.2.3 “Printer Mechanism Removal”.) Release 2 hooks of the PG sensor securing it to the left frame with tweezers and Release 2 hooks of the release lever position sensor securing it to the right frame with remove the sensor. EPSON LX-300+II/300+II RTP/1170II Revision D 4.2.7.10 PF Motor Assembly Removal 4.2.7.11 Paper Feed Mechanism Disassembly Remove the printer mechanism. (See 4.2.3 “Printer Mechanism Removal”.) Remove the printer mechanism. (See 4.2.3 “Printer Mechanism Removal”.) Remove the platen grounding wire from the platen. EPSON LX-300+II/300+II RTP/1170II Revision D 4.2.7.12 Paper Guide Removal Remove the combination gear, 8.5, 25.2 from the right frame.

Remove the printer mechanism. (See 4.2.3 “Printer Mechanism Removal”.) Combination spring, 1.18 Hook at the right frame Remove the platen. (See 4.2.7.2 “Platen Mechanism Removal”.) Plain washer, 5.2 x 0.3 x 10. EPSON LX-300+II/300+II RTP/1170II Revision D Release 1 hook at the left frame securing the base frame and remove it by pulling it to the rear.

When the paper guide is removed or replaced, perform the platen A D J U S T M E N T. C H A P T E R ADJUSTMENT.

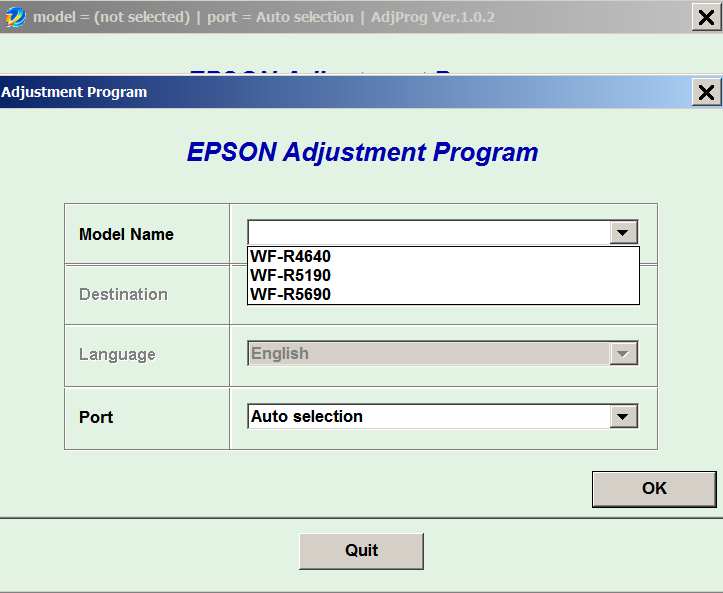

EPSON LX-300+II/300+II RTP/1170II Revision D 5.1.2 Running the Program Adjustment Tool Start up the Adjustment Tool for SIDM, and you will see the following screen. With the Adjustment Tool for SIDM, you can perform: Get Printer Information PG Adjustment . EPSON LX-300+II/300+II RTP/1170II Revision D 5.1.2.1 Sequential adjustment mode When you select the Sequential adjustment mode, the following screen will appear. Adjustment screen Follow the instruction shown on the screen to perform the adjustment. When you have performed one adjustment, a next adjustment screen will appear. Perform all the necessary adjustments.

EPSON LX-300+II/300+II RTP/1170II Revision D 5.1.2.2 Particular adjustment mode When you select the Particular adjustment mode, the following screen will appear. Particular adjustment mode Select an adjustment or additional function you want to perform, and click the OK button. EPSON LX-300+II/300+II RTP/1170II Revision D 5.2 Adjustments START 5.2.1 Platen Gap Adjustment Perform the platen gap adjustment when you have performed any of the following: Move the carriage unit to the left end. Removing or replacing the printhead unit (See page 70.) .